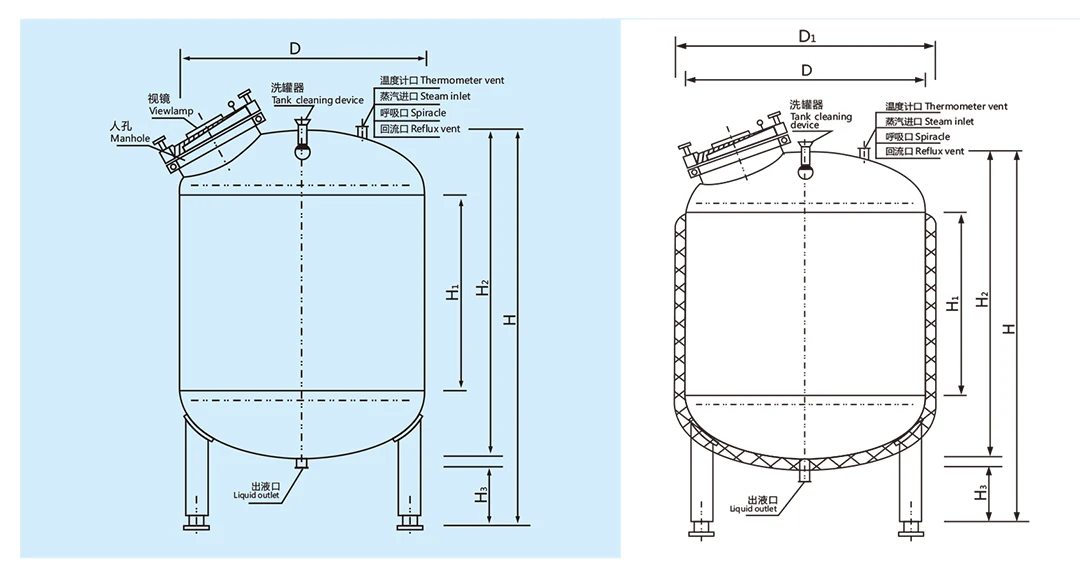

Q1. How to order tank ?

Fisrtly, please confirm which application for tank, such as food, beer, pharmaceutical, chemical or other industry.

Secondly, pls confirm which material, capacity, presure, temperature, material composition,need or not agitator, jacket, insulation, and so on.

Q2. What’s surface finishing?

Internal surface is 0.4um to up standard to pharmaceutical standard.

External surface is 0.8um

Q3. What’s maximum capacity ?

We can produce 50000liters for tank, which can be designed vertical and horizental.

Q4.How do you control the quality?

Quality control is very important to avoid material mixing and poor quality.We control the quality from beginning to the end.We only have 304 and 316L two different materials.100% inspection on raw material.During production,different materials in different place.After materials are finished,we choose 10% for inspection.If there is 0.1% problem in 10%,then no excuse to go ahead for inspecting 100% of the materials.

After tanks are finished, and we will hyraulic test for each tanks to make sure no leakage and safe.

Q5. What’s the payment terms?

For small testing orders,we accept Paypal,Western Union,T/T and credit Card.

For mass orders,we accept T/T and L/C.

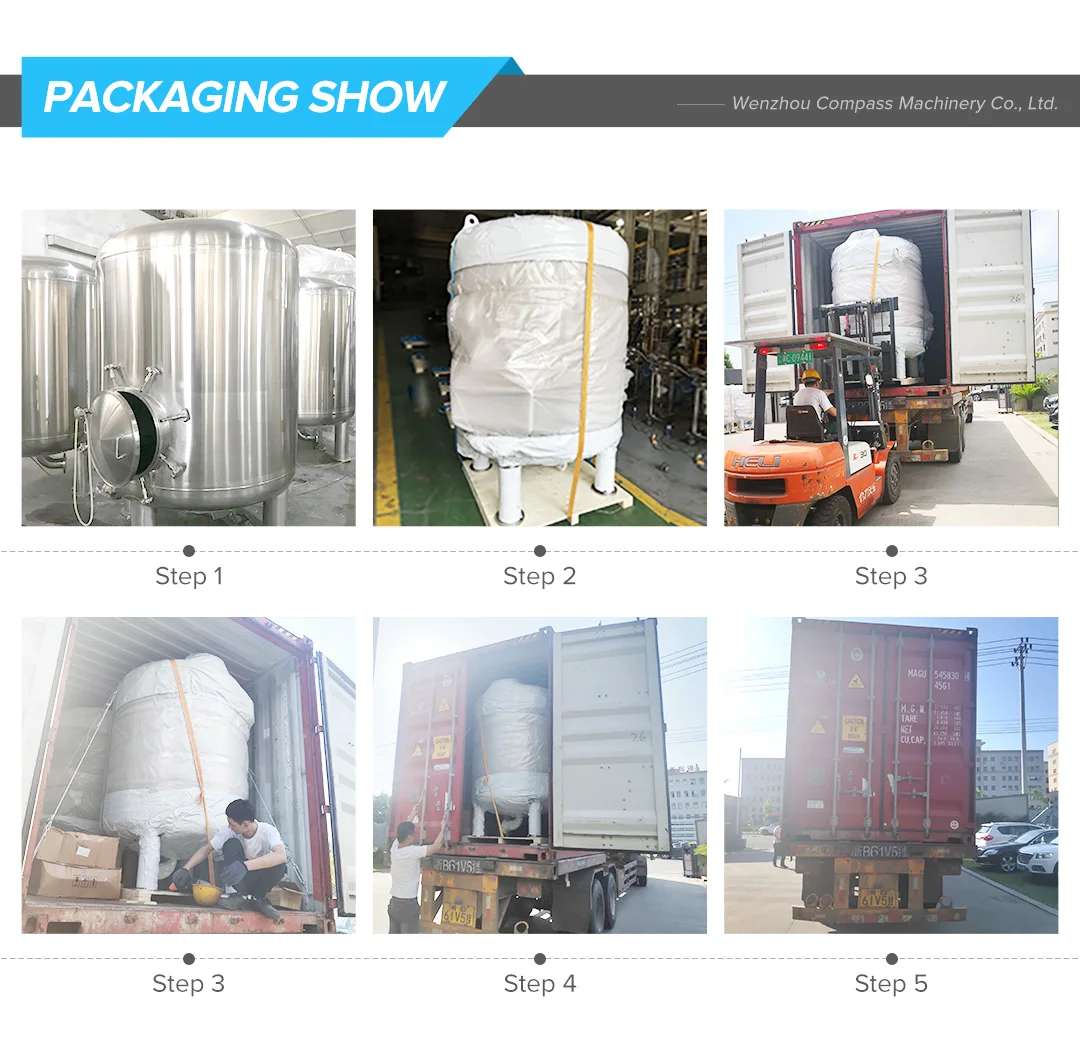

Q6.How long is your delivery time?

For normal production in 10-15days.For bulk order in 20-25days.

Q7.Warranty

One year warranty for all of our stainless steel products,but excluding wearing parts

Q8.More questions are appreciated.